- vijaylaxmiimpex5@gmail.com

- Mumbai, India.

Get In Touch

Get In Touch

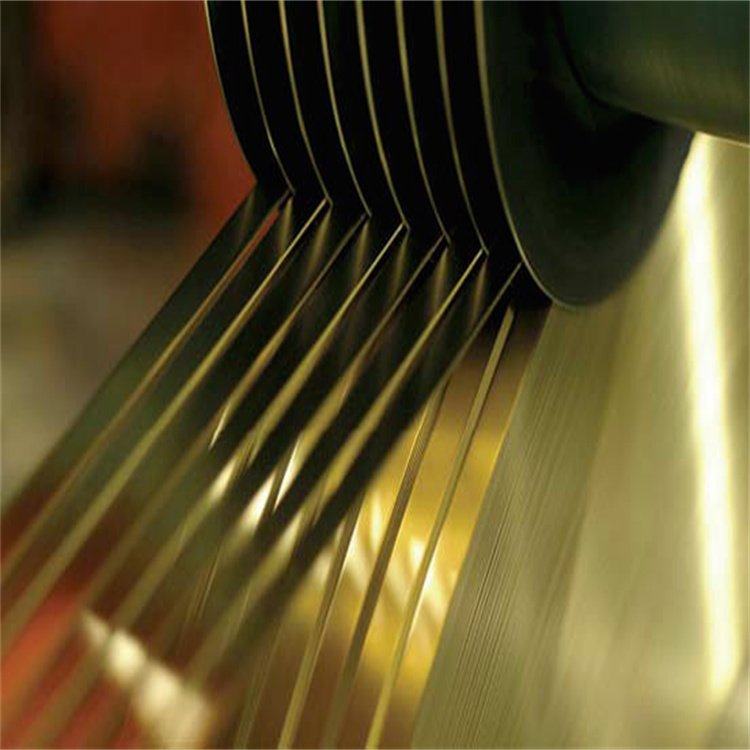

Slitting is a high-accuracy-cutting process of wide metal coil, accurately straight-cut to narrow coils with high-performance rotary blades. The process is crucial with the help of which coil material is prepared to be manufactured in another way, e.g., stamping, forming, or rolling. Our facility provides a quality slitting of coils with high degree precision tolerances and burr-free edges services of a variety of metals such as stainless steel, carbon steel, and special alloys.

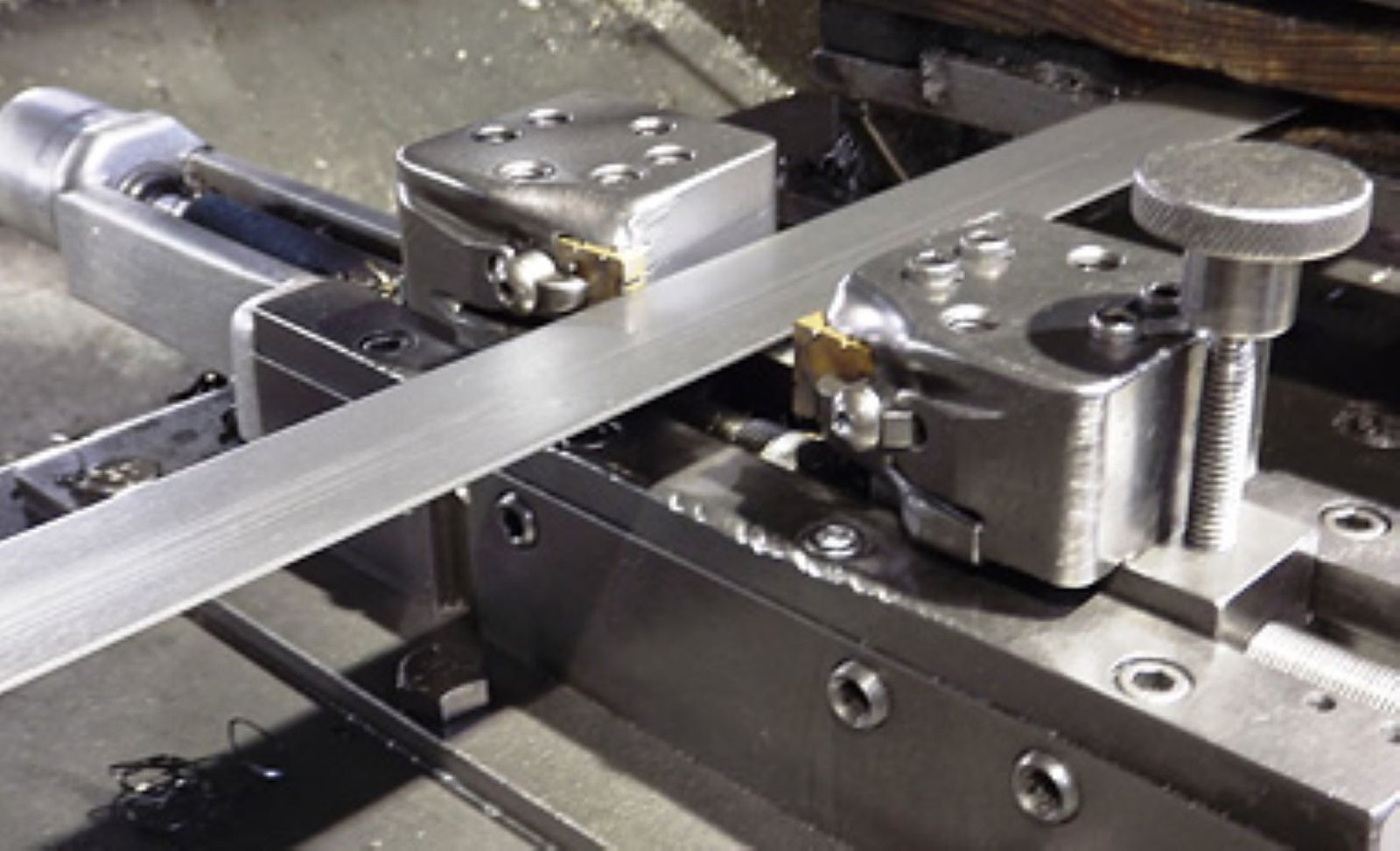

Narrow Width Precision attributes to narrow widths with close tolerances of measurements during the slitting and processing of materials, either in the form of metal coils or metal strips. It guarantees continuity of quality and precision dimensions for use in sensitive activities in sectors such as electronics, automotive, and aerospace.

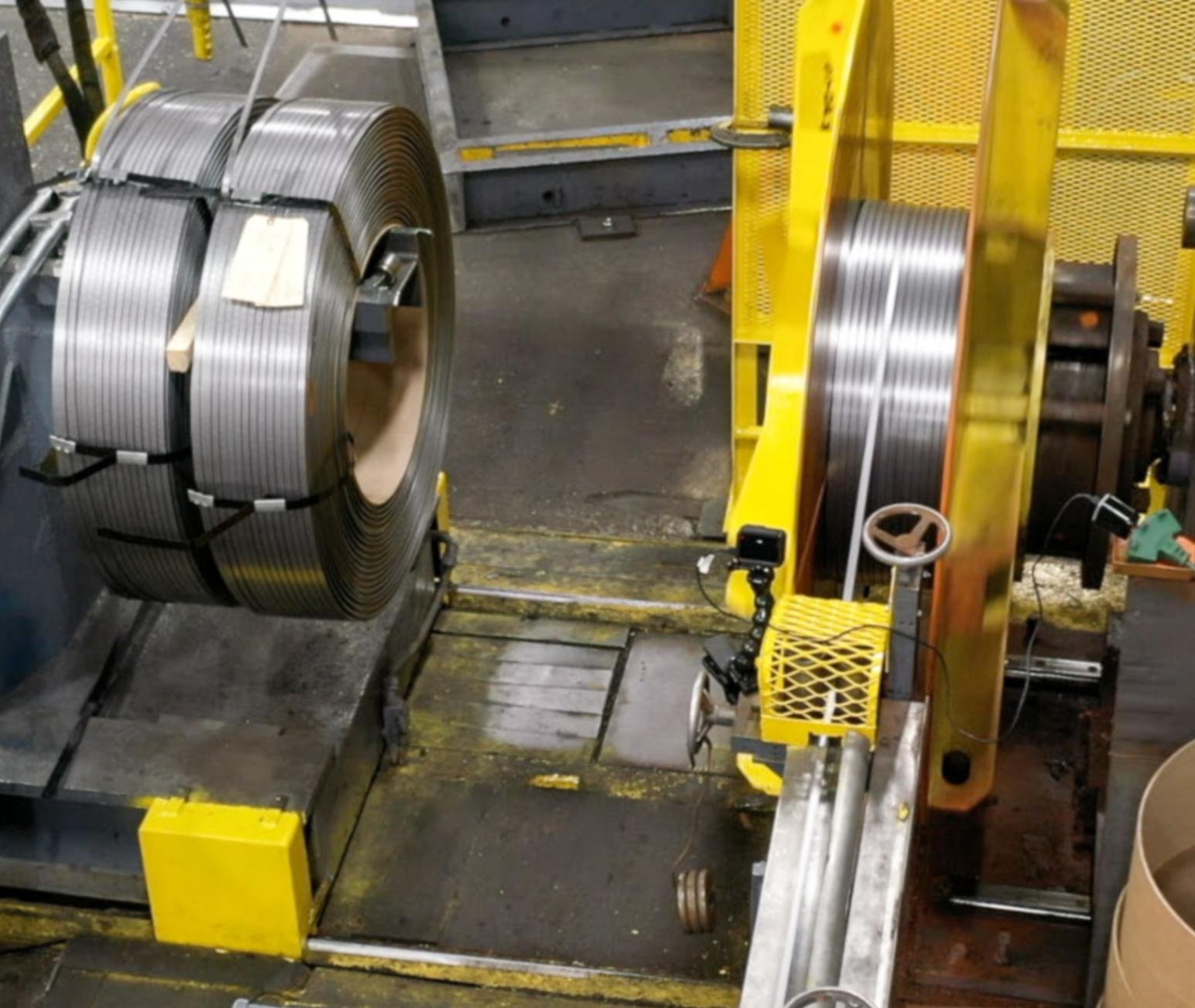

Oscillating Slitting is a novel manufacturing process of metals in which narrow strips of a coil and wound overlapping and alternating formation onto one spool. The process maximises the length of film per reel whilst minimising changeovers and wastes, which helps to maximise efficiency, perfect for thin material fine slitting in the electronics, medical, and precision industries.

Shearing coils and plates is an activity whereby metal coils or flat plates are cut into different sizes in straight lines where no melting and burning of the metal is realized. It also guarantees clean edges and tight tolerance so it is best suited to pre-fabricating materials that will later be used by other processes descriptions of the main types of cutting methods used in the construction, automobile and heavy engineering industries.

Heat-treated and cut to length in coil Cut to Length (CTL) in coil is when metal in coil form is unwound, straightened, and accurately cut (or rolled) into flat sheets of defined lengths. This process will allow correct sizing and less wastage of material which is ideal to make ready to use sheets to use in fabrication, construction, and industrial ventures.

Round Edges in Coils: this is where sharp edges are removed on slit or cut metal coils to produce rounded edges. This increases safety in handling, avoids edge cracks, and increases surface finish, making it an appropriate processing system in electrical, automotive and appliance manufacturing where edge quality is crucial.

Round Edges in Coils: this is where sharp edges are removed on slit or cut metal coils to produce rounded edges. This increases safety in handling, avoids edge cracks, and increases surface finish, making it an appropriate processing system in electrical, automotive and appliance manufacturing where edge quality is crucial.

Cold rolling refers to a metalworking process where metal coils are pressed through rollers at ambient temperature, to thin the workpiece, to smooth the metal surface, and to increase its mechanical strength. Contrary to hot rolling, cold rolling will have no heating, thus leading to improved length and width accuracy and finishing.

PVC Coating PVC Coating refers to the method by which metal, most commonly coils or sheets, are covered with a polyvinyl chloride (PVC) layer to improve corrosion resistance, durability and physical appearance. It offers moisture, chemical and abrasion protection and as such finds use in building, household equipment and in artisanal decorations.

Export Packing is the art of firmly packing goods to sustain long-distance journeys, handling, and weather conditions during overseas shipping. They encompass such means as wooden crates, pallets, shrink wrapping, and moisture protection.

Palletizing consists of loading and fixing a product or materials on a pallet in order to ease and streamline safe handling, safe storage of goods, and safe transportation. In manufacturing and factory conditions, palletizing has been beneficial in the efficient arrangement of logistics, as in such facilities, cargo can move in bulk either by the use of forklifts or the use of pallet jacks.

Wooden Pallets are strong timber structures that are good for stacking, storing, and safely transporting of goods. They are very useful in terms of support and stability when handling or shipping. A typical application is the warehouses, logistics, and export packaging.

Crates are robust, box-shaped containers made of wood, plastic, or metal, used for packaging and transporting heavy or breakable products. They are remarkable in their impact and environmental protection. It is frequently utilized in industrial export packaging and shipping.